Matsuzawa Rockwell Hardness Tester Mogura Series

Economy and High Quality Rockwell Hardness Tester – High Performance. High Precision. Low Cost. Available in Rockwell and Superficial type. Presented by MSP Metrology (M) Sdn Bhd from Matsuzawa Japan

Features

1. MoguRa-a

High visibility with LED backlight

2. MoguRa-a | MoguRa-d

High visibility with Large and long sample testable

※ 1 As compared with the conventional our products

※ 2 Relief hole is required in the base to use at maximum height LED backlight

3. MoguRa-a | MoguRa-d

Easy switching of test force with knob.

4. MoguRa-a | MoguRa-d

Good quality product with tasteful design.

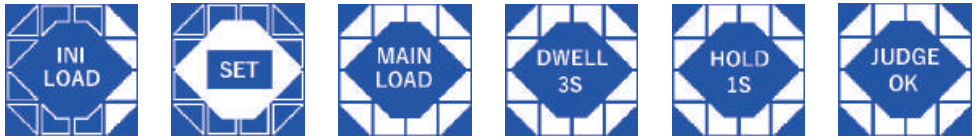

5. MoguRa-d

Intuitive operation with matrix panel

Real-time countdown display of holding time

6. MoguRa-d

All Rockwell scale testable.

※ 3 MoguRa-d3 only

7. MoguRa-d

Operability is greatly improved by automatic braking (optional)

8. MoguRa-d

Plastic hardness test.

Accessories – Indenter

R001

Diamond Indenter

R011 / R200

1/16″ Ball Indenter

R012 / R201

1/8″ Ball Indenter

R013 / R202

1/4″ Ball Indenter

R014 / R203

1/2″ Ball Indenter

Accessories – Anvil

R111

200mm Round Table

R101

60mm Flat

R103

V-Spot

R105

V-shape Large (Sample diameter 8 – 50mm)

R104

V-Small

R102

Spot

Accessories – Jig

R131

Vari-rest

R132

Jack-rest

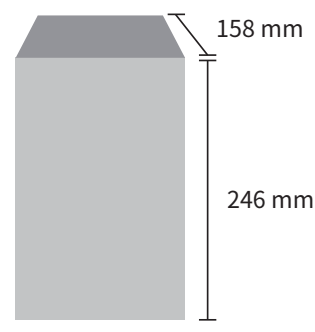

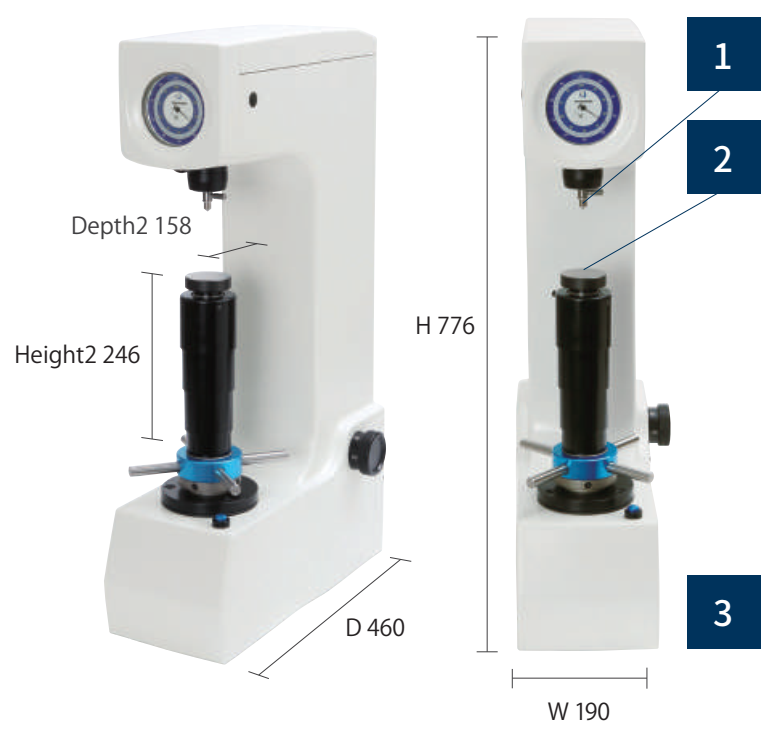

Dimension and Weight

1. Indenter

2. Anvil

Width 190 mm

Depth 460 mm

Height 776 mm

Weight 65 kg

3. Jig

Specifications

| Type | Analog Type | Digital Type | ||||

| Model Name | MoguRa-a1 | MoguRa-a2 | MoguRa-d1 | MoguRa-d3 | ||

| Test Type | Regular Rockwell | Superficial Rockwell | Regular Rockwell | Regular/Superficial | ||

| Display | Dial Gauge | LCD | ||||

| Preliminary Test Force | 10kgf | 3kgf | 10kgf | 3kgf, 10kgf | ||

| Total Test Force | 60, 100, 150 kgf | 15, 30, 45 kgf | 60, 100, 150 kgf |

15, 30, 45 kgf 60, 100, 150 kgf |

||

| Scale | Included Indenter | DIA | A D C | 15N 30N 45N | A D C |

A D C 15N 30N 45N |

| 1/16″ Ball | F B G | 15T 30T 45T | F B G |

F B G 15T 30T 45T |

||

| Optional Indenter | 1/8″ Ball | H E K | 15W 30W 45W | H E K |

H E K 15W 30W 45W |

|

| 1/4″ Ball | L M P | 15X 30X 45X | L M P |

L M P 15X 30X 45X |

||

| 1/2″ Ball | R S V | 15Y 30Y 45Y | R S V |

R S V 15Y 30Y 45Y |

||

| Force Control | Preliminary Test Force | Manual | Manual | |||

| Total Test Force | Manual (Electric load/unload) | Manual/Auto Select | ||||

| Dwelling Time | Preliminary Test Force | – | 1 ~ 99s | |||

| Total Test Force | 1 ~ 99s | 1 ~ 99s | ||||

| For Recovery in F0 | – | 1 ~ 99s | ||||

| Standard | JIS Z 2245, JIS B7726, ASTM E18-19, ISO 6508-1, ISO 6508-2 | |||||

| Specimen Size | Max. height 246 mm, Max. depth 158 mm | |||||

| Dimensions and Weight | W190 x D460 x H776, Weight 65kg | |||||

| Power Supply | AC100-240 50/60,Hz | |||||

| Test Cycle | Automatic (Pre Load – Test Load – Release Load) | |||||

| Test Load Dwell Time | 0 to 999 sec | |||||

| Auto Brake Option | – | Yes | ||||

| Plastic Hardness Test | – | Yes (JIS K 7202-2) | ||||

| Data Output | – | RS-232C, Data Memory Max. 99 | ||||

| Statistics | – | Max., Min., Average, Standard Deviation | ||||

| OK/NG | – | Upper/Lower Limit Select | ||||