Cedar Torque Tester WDISR-IPS Series

The WDIS series is easier to use and has higher performance. Manual torque driver and wrench management, automatic semi-automatic tool management, inspection of screw tightening and relaxation torque. Presented by MSP Metrology (M) Sdn Bhd from Cedar Japan.

Features

WDISR-IPS series (-IPS05C/5C/20CL)

Can be installed to manage various torque tools with a small detector.

- A color display that can display various information.

- Data output is standard equipment for both USB and RS232C.

- Numerical values such as pass / fail conditions can be set up to 10 channels.

- The pass / fail judgment is displayed in color for easy understanding.

- Built-in battery drive.

- Various commands can be input from PLC or PC.

- The WDISR-IPS series includes WDISR-IPS05C, WDISR-IPS5C, and WDISR-IPS20CL.

A type that can be disengaged from high speed with a clutch at once

Use OW joint

Screw tightening robot etc. A type that slowly re-tightens with current control

Use screw cube

Color Display that can Display Various Information

Data output is Standard Equipment for both USB and RS232C

Setting Various Measurement Parameters

Works with PC and PLC

Command list

Clear signal: Clears the display and outputs the held numerical value as data and saves it in memory.

Measurement mode: Change the measurement mode.

Measurement channel: Change individual channels for which conditions such as pass / fail judgment are set.

Peak hold upper limit: Change the pass / fail judgment upper limit of the current channel.

Peak hold lower limit: Change the pass / fail judgment lower limit of the current channel.

Peak down lower limit: Change the peak down judgment start lower limit of the current channel.

Real-time output lower limit: Changed the output lower limit of real-time output.

Auto clear time: Changed the time to automatically clear after the measurement is completed.

Buzzer notification: Changed the buzzer notification method.

Full Specifications

| Specification | WDISR-IPS05C | WDISR-IPS5C | WDISR-IPS20CL | |

| Applications | It is a torque measuring equipment to measure the tightening torque of tightening tools (electric screwdriver, torque screwdriver, etc.) in screw tightening work. | |||

| Power Supply | Internal battery (12 hours continuous operation time, 3 hours charging time) |

|||

| Rate Input Voltage | 12V DC | |||

| Measuring Range (At time of Track) | 2.0 ~ 500 mN・m | 0.020 ~ 5 N・m | 0.20 ~ 20 N・m | |

| kgf-cm lbf-in mN-m cN-m |

kgf-cm lbf-in N-m cN-m |

|||

| Accuracy | ±0.5% (if 499 or less digit ±3 digit) |

|||

| Sampling Rate | 1000 data / sec | |||

| Measuring mode |

PP Peak hold | Measure the peak torque (with data output) | ||

| PD Peak down | Measure the first peak torque (with data output) | |||

| C Real-time output |

The data output cycle is approximately 180 data / 1 second. (with data output) |

|||

| TR Track | Mainly used for calibration. (without data output) | |||

| Data Output | Wired (ASCII format) | |||

| Memory Size | 800 data | |||

| Auto-power Off | Power off after 10 minutes of non-use | |||

| Accessories, Attachments | Detector (refer table below) | |||

| Detector cable | ||||

| Joint OW-025 | Joint OW-10 | Joint OW-20 | ||

| Cube (H20×W20×D20) | ||||

| SC-1 with the screw hole of M1, M1.2, M1.4, M2 and M3 | SC-2 with the screw hole of M2.6, M3, M4, M5 and M6 | SC-3 with the screw hole of M4, M5, M6, M8 and M10 | ||

| AC adaptor | ||||

| Rubber foot | ||||

| Result of calibration, Certification on calibration, Traceability system figure | ||||

Detector

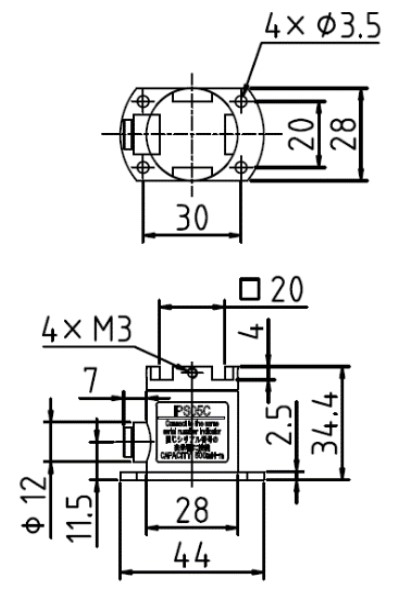

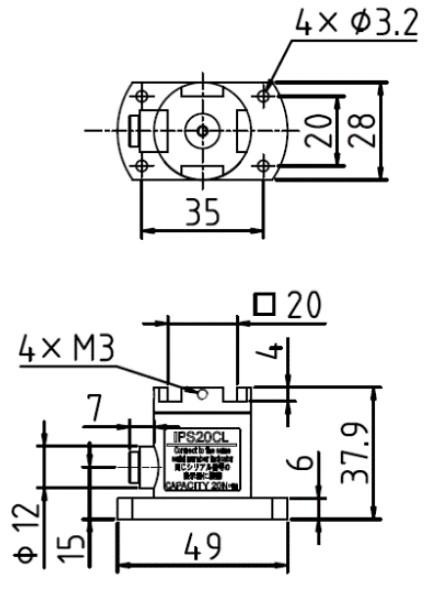

| Model | IPS05C/5C | IPS20CL |

|

|

|

| Socket | ∅20mm | |